Eyelash extensions are a staple product in the beauty industry, and for online eyelash brand owners, understanding the manufacturing process is crucial. The quality and materials used to create eyelash extensions directly affect the final product’s performance and customer satisfaction. This article explores the step-by-step process of how eyelash extensions are made, focusing on the importance of quality control and premium materials like PBT fibers.

Cosey eyelash extensions are made from a soft, plastic fiber called Polybutylene Terephthalate (PBT), a thermoplastic material that is heated and shaped into curls. The process involves inspecting raw materials, creating semi-finished products, shaping the fibers, and performing multiple quality checks. This ensures that every batch of eyelash extensions meets the highest standards for B2B buyers.

Step-by-Step Eyelash Extension Production Process

1- Raw Material InspectionEach batch of raw materials undergoes a thorough inspection to guarantee they meet our strict standards for thickness, color, and stability. Only the finest fibers are selected for production.

2- Preparation of Semi-Finished Product

The inspected raw materials are placed into custom molds to form semi-finished lashes. This step ensures consistent shape and volume across all batches.

3- Cut Excess Lash Fibers

The semi-finished lashes are carefully cut to achieve the desired length. Precision in cutting is essential to meet specific customer requirements.

4- Curve Creation

To create various lash curls, the fibers are rolled around tubes of different diameters. High temperatures are then applied to set the curl while simultaneously sterilizing the lashes, ensuring they maintain their shape over time.

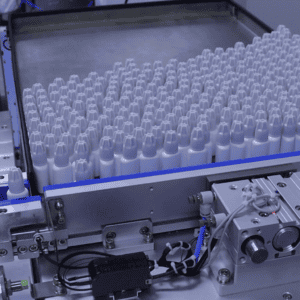

5-Put Lashes on Paper Cards

The finished lashes are meticulously placed on paper cards, ready for final inspection. This step ensures they remain in perfect condition during transport and storage.

6-Final Quality Inspection

Before leaving our factory, each lash undergoes a final quality inspection. This rigorous check confirms that only flawless, high-quality lashes are delivered to our clients.

Understanding how eyelash extensions are made is essential for B2B buyers and lash brand owners looking to source high-quality products. The production process, from raw material inspection to final quality checks, ensures that each lash extension is crafted with precision and care. By choosing products made from premium materials like PBT, businesses can guarantee customer satisfaction and build a strong reputation in the competitive lash industry.