The beauty industry relies heavily on high-quality strip lashes to meet consumer demands. Understanding the intricate production process of strip lashes can help brand buyers and online shop owners make informed purchasing decisions. This article breaks down the entire process, from raw material inspection to the final product packaging, ensuring you know exactly what you’re investing in.

Strip lashes are produced through a meticulous process that begins with raw material inspection and continues through several stages, including style creation, layering of fibers, and high-temperature styling. The final step involves placing the lashes on trays, ready for packaging and distribution. This step-by-step approach ensures consistency and quality in every batch of lashes.

Let’s dive deeper into each step of the strip lash production process to understand how quality and precision are maintained.

Raw Material Inspection

The first step in producing high-quality strip lashes is thorough raw material inspection. This ensures that only the best fibers are used, which is crucial for creating durable and appealing lashes.

Creating Lash Styles

After selecting the best materials, labors would create various lash styles. This involves designing the lashes to meet different market demands, from natural to dramatic looks.

Combining 3-5 Layers of Fibers

To achieve the desired thickness and volume, labors would layer 3-5 fibers together. This step is critical for ensuring the lashes are full and have the right amount of dimension.

Getting Semi-Finished Lashes

Once the fibers are layered, the product enters the semi-finished stage. At this point, the lashes have taken shape but need further refinement.

Cutting Excess Parts and Reserving Lash Tips

Precision is key here, as excess fibers are trimmed away, and the lash tips are carefully reserved to ensure a clean, natural look.

Creating the Curve with Aluminum Tube

The signature curve of strip lashes is achieved by using an aluminum tube, which shapes the lashes to fit the natural curvature of the eye.

High-Temperature Styling and Sterilization

To lock in the shape and ensure hygiene, the lashes undergo high-temperature styling and sterilization, making them safe and ready for wear.

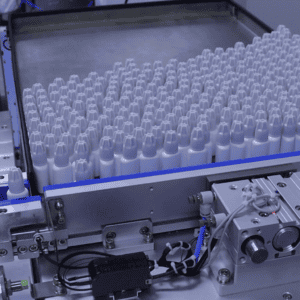

Placing Lashes on Trays

The final step involves carefully placing the finished lashes on trays, where they are ready to be packaged and shipped to customers.

Understanding the strip lash production process would help buyers and online shop owners to make informed decisions when sourcing products. By focusing on quality at every step, from material inspection to final packaging, manufacturers ensure that each set of lashes meets the highest standards.